Durbahn-Alternator.

Durbahn-Alternator..... May 1.2004 :

The mould of the lower fairing is

done,maybe I'm able to built the first Positive on Monday.

Somewhat 150 hrs the modelwork of this Section took,but has been worth it.

Also close to be done: the whole

Clutch-setup .Somewhat mid of May I'll post the Pictures here.

A bit complicated thing is-I've to re-machine the teething of the

race-transmission where the hub is put on,and also I've to shorten the

transmission-axle somewhat 25 mm (1") . Even if the Basket and hub have a

bit more width than the Duc-OEM clutch Setup (1cm ,because it's running with 30%

more clutch/friction plates) I'll end up with the whole assy with close to

1" less extension to the outside,so much less crash sensitive.

Yesterday I received the remaining electronic Components to built this very special rectifier which I need for the superspecial Alternator. I think I've written this somewhere else : if this Alternator works, I can cut from the crank ~ 6cm (2 1/2 "),and I estimate ,that only the weight which I can cut from the crank is 50% of the weight of my whole Alternator !

Those who know me,may foresee,that nothing like just exchanging a fork,some wheels,a shock,some carbon plastics,an exhaust ....etc will appear here. Such Bits you just buy and bang on .

He- yes ,a nice word " bolt on ", and I wished there would have been a way to develope something for the Duc ,just " bolt on" , as I've partitially done for the RC.But the Duc is so misconcepted in main areas,that there's no possibility to develope a large # of simple to swap Items .

You have to be radical, otherwise you get nowhere.And it's not my deal to built a Ducati with a full fuel weight of 195 Kilogramm (430,46 lbs)

Those who intend maybe to wait until my

Bits are developed and not buying something different somewhere,have to know :

it's no trainee-program here .

Means: The Airbox fits together with the

Fueltank-dummy with the Air-Intake,with the Fairing,with the Fueltank with the

Radiator with the Exhaust with the subframe with the Tailsection with the

Battery-bracket with the wire-harness.

I think,that's it.

It's moreless my personal project.

I like it to be in the Situation that I don't have earn money with this

rebuilt,sit back,enjoy this Project....

Radiator

OEM-Alternator and starter

gear mod

....which could give up to 280 Watt !

Well, still not clear yet,on the Pic you'll see the raw board-layout for the

rectifier,which is incredible complicated to fab,and of course ...not done at

present (but one rectifier-prototype is running !). Because I'm not sure about

the Power-Output I need - because I'm unable to foresee the Ampere's I need -

I've ordered lots of different transmission-wheels, so I can go down to as low

as possible rpm for the Alternator .

I ned the headlight power-supply,the lambda-sensor heatening for Motec and have

to drive the Injectors + the fuelpump. This is raw estimated 160-170W which

should be reached by the Alternator at less than 3500 rpm,means that should be

the rpm,where's neither charge nor discharge.

Oktober 09: Testrun

Alternator  Power output

Power output

........Clutch

........Clutch

1: The clutch-setup

,moreless done.When I've concepted the clutch I estimated the whole Setup on 2580 gr,that's less than half of the OEM-Setup. I've put the Bits on the scale now,and even if I havn't received the Aluminum clutchplates yet (which-as I've been informed,are at 315 gr ) I should end up at :

1960 gr for clutch-Basket incl. gear , hub

, pressure-plate

247 gr for friction-plates

313 gr for clutch-plates

? gr for springs...hm,forgot to put them on the scale,but lets sum up what

we know,and we're at 2520 gr for everything without the springs and

srews.Well,I'll find some superflouos Material somewhere to drill some holes,so

I'll definately stay below 2580 gr ...or 5.69 lbs !!!

November 1.2004 :

Well, all in all, I put it on top ,a

clutch-summary:

I know that most or all GP-Bikes have a dry-clutch, and those Bikes are the

fastest around .

Most Superbikes have a wet-clutch,and their lap-Times are maybe 1 sec.

slower .

GP bikes may have 60 hp more and 30 kg less..and of course: a dry-clutch...and

they are 1sec. faster.

Well...a wet-clutch is eating

horsepower,that's why the new I4's do only have 170 hp and every dryclutch

equipped Bike ............ok............in one : there are fast Bikes on Market

with a wet clutch,and slow Bikes with a wet clutch,kinda reverse.

Seriously,what I want :

1: a light clutch

2: a reliable and durable clutch

3: clutch slipping sentiment

4: low declutch handforce

5: lowest possible crash sensivity through less outside extension of the whole

clutch

.... unobtrusive as possible,regarding maintenance,noise,function .

No Item of worth I thought,so as a first

test I machined the OEM clutch-Cover to fit for my clutch,wasn't a big

deal .

....only had to remove the inside contour .

....only had to remove the inside contour .

The whole Clutch setup. Had to machine the primary gear widht from 17mm (..I think..) down to 13mm,and removed also some Material from the inner circle.As I see it now,the whole clutch might be a bit overdimensioned ,9 clutch-Plates and 10 Friction-Plates,a gigantic friction-surface,but therefore it'll be reliable as hell accompanied by a very good clutch-slipping sentiment and also I might be able to lower the spring-preload,which will lead into much less handforce to pull the clutch....or even less,if I consider that I will mount my cable clutch conversion too.

As for the weight : 2570 gr. I estimated

when I started the clutch-Project,but this has been a bit too

optimistic..........the scale today showed (incl. gear,bearings..completo

complete..) 2830 gr.

Somewhat 80 -150 gr are still hidden somewhere (80 gr. in the hub,rest

elsewhere),and of course some additional weight saving I'd have if I'd go

for oneandone fricion/clutchplate less. Well,I'll check that .

So here we are now, 15 mm (0.62") the

clutch is showing out of the cover . As far as I remember the OEM Duc Clutch is

at 43 mm ......that's 28 mm less !!

I've

seen a guy on the track with his 999,unspectecular low sided his Bike,cpl. hub

damaged ,those days should be gone with this clutch.

I've

seen a guy on the track with his 999,unspectecular low sided his Bike,cpl. hub

damaged ,those days should be gone with this clutch.

And of course it's a aesthetical thing, a

flat maybe 18mm machined Clutch-cover is a very different thing compared to what

Ducati put on the Bikes .But....when I started with my Project I wasn't unable

to re-enact at all why the clutch cover was made by heavy mild steel sheet metal

, but on the track I learned to understand : even this one is not massive

enough.

I do not want to imagine what will happen to the clutch at a crash with these filigrane open Carbon -Covers mounted .

........btw it's a funny # : only the Duc Clutch-gear

was 300gr heavier,than my RC51 Basket INCL. gear ! So somewhat 0.66 lbs !

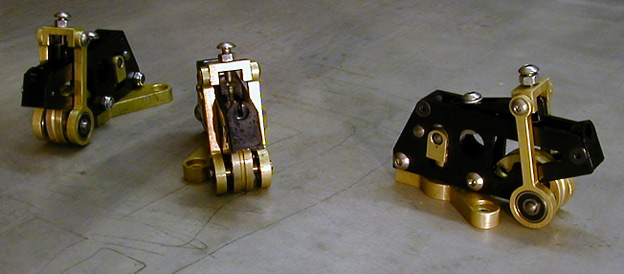

my RC51 Clutch-Basket

It's January 30.2004 today, and a few hrs ago I've finished the draft of the Duc clutch basket. From what I can estimate just looking at the draft, this basket/hub-assy will be very light,but durable.

It's not the same concept as all the other

clutch baskets/hubs/assy's which are available.

It's something maybe crazy or stupid . But what I want:

-Durability

-as quiet as possible

-as low declutch force as possible

-less extension to outside (approx 1")

-less diameter (it's calculated now -8mm)

- and of course,the weight. The duc-Clutch OEM has 5.3 kg,and what I can see now I probably will be able to decrease the weight down to 2.5 kg,that's more than 50% (Everything calculated including gear)

.....Fairing

.....Fairing July 4 :searching for a conclusive design

......and Radiator Air-Outlets

......and Radiator Air-Outlets

Pics from Fairing-Modelwork,lower fairing nearly done

This fairing will cost me hundret's of hrs,and I'm moreless afraid by this forecast,but however,someone has to do this drudgery.........

Regarding whats scheduled with the Duc-fairing I proceed much faster than expected .If you have a closer look you will notice,that I simple started with a MV fairing,which of course doesn't fit ,additional it's much too broad everywhere,the lower section is too short ...and and and.But that's nothing which is not to solve .Of course in the End not a lot of the MV fairing will remain .

I hate that work, but someone has to do it. I've seen the re-modeled 999 fairings/Tailsections on Market,which are moreless simple reshaped,thats not me. Of course it'll be a damned drudgery,same as it ever was,but I'm free to place the Intake where I want, the headlights.........and because I've got no canister below my Tailsection, I'm able to choose the best design which I have in mind...............

.....that's a nice advantage I

have,meanwhile .I've got lot's of different moulds here for fairings and so

on,so if I notice,that it could be of some use,than I just copy a certain area

of maybe a fairin,and adapt it to the one i'm working at .So I.E. i've copyed

thje Airduct covers of the Duc

and made them fit by cutting not necessary Sections

Of course its a lot of work,nearly each cm2

I have tore-shape to make all fit and nice looking,but should be worth the

work,I hope

Hehe-that's is,just calculate the Carbon-Subframe

at 600 gr,the Tailsection at 900gr,that's it,1500 gr........ a bit more than 3

lbs for everything

Oktober 08: Fairing upper detail .

right side

right side

..........Electronic

(ECU) MOTEC-ECU

..........Electronic

(ECU) MOTEC-ECU

That was a fine thing,when I dissasembled the Duc- I did not even wasted a first thought about which wire is leading where and doing what,just teared all apart and threw it in a box....someone needs a wire-harness ? Doing my own thing,probably-as long as I'll be in Motorcycles- I never will rack my brain again about any OEM ECU and how to manipulate it, I simple use Motec.

A few Advantages:

-everything free programmable

- Datalogger

-Quickshift integrated

-Shiftlight intergrated

-Lambda controlled

......maybe disadvantage: Price. But calculate yourself,what you'd pay for components mentioned above

....Fueltank

....Fueltank

Addittion July 05.04 :maybe I'm at 15

Liters,maybe 16 liters,really hard to estimate.....but it is as it is,I've used

every available space but with one hand a clearance to Engine of ~ 1/2 "

and on other hand also ~ 1/2 " to the fairing.I will built the

fueltank very crash-resistant,have got a good Idea,but more therefore when the

Time comes.

You may have seen some Pics of what I've removed left hand side,but here's the

latest Pic I can give you,everything prepared for the Fueltank:

.............here's the leftrear view of

the Fueltank,on top you may notice the flat round surface which gives the

opportunity to mount a filler

........something I probably will do for

trackdays : as far as I know,most of us are trainees regarding riding on track

constantly fast,so somewhat 25 Minutes you're able to ride under full

concentration.

Therefore approx 8-9 Liter Fuel is enough,that's why I think to built myself a

special fuelcapacity decreased Edition for trackdays......

March 2004:

At present it looks like 14 Liters,same as

my RC51 Fueltank. Some may say that's too little,some that it's more than enough

Volume. It depends on,what you do. For myself I'd say 8 liter would be

enough,because I intend to use the Duc at the track,and I'm not in physically

condition to ride fast more than max 27 minutes. which probably would end up

of 7 - 7.5 Litre Fuel consumption .However, I neither built a touring

Bike,nor a one which looks like a fast Bike by maybe all those nice bling

Magnesium parts I've put on...............

What I can say now,probably some have not expected it in an other way : no Fueltank on top !

At

....

Alternator and starter gear (+drive)

....

Alternator and starter gear (+drive)As always I try to lighten up the

Alternator and the starter gears and drive either by modification or by a

new (smaller dia- ) Alternator. This Time I decided to go for the OEM Alternator

for a while. The Alternator itself is not so heavy,moreless it's the flywheel (

!! flywheel ?? Yes ! ) behind Alternator,which I've modified/lightened extreme .

.....so right side of the Pic you can the ex-flywheel,the ring which is left

over after machining,left side the clutchgear inner part which is also left over

now.Well, that probably doesn't say much to you if you don't know how it looks

in OEM shape.

So here's the starter drive after machinig it:

The starter-gear (which was solid before ):

The Alternator (starter-drive) carrier ,if

you know how this thing looked before,you may be able re-enact that it has been

a bit of work to mod it :

Early 2004 : assorted

Wellok,I thought the RC51 underseat-can was complicated to fab ( took 22 hrs ),but this was nothing compared to the 999-Can I've made......... .3 full days I've worked like a dog for that strange Idea I wanted to realize at the 999. Now it's done so far,Sunday 28.12 I'll carry all tho my welder and hopefully I get the Bits back 31th. I decided to post the pics here,when it's done.

Rebuilt 5

A Motec-ECU ,to replace the OEM crap, is ordered,I've to write the tables for Injection/Ignition /Fueltables /Crank index position ,but a lot of work is done,because I've got the tables for sensors from RC51 for Map and Air and Water-temp already written ,so I simple use those sensors.

Some more explanation and Pictures :here

Rebuilt 4

that's the clutch ! I've got my own Ideas

to built a very lightweight reliable unnoisy clutch............don't want to

tell too much now.But of some Advantage is the spring-preload gauge I've built

recently to check the spring of different motorcycle-clutches and also

valvesprings

Rebuilt 3

Saturday 12.20.03 I started to built the headers for the duc, the headers are done so far know(spot-welded).I cannot tell how this Exhaust will work or look,because one hand I'm not sure how it works,and on the other hand I don't like the Idea of being copyed BEFORE the Bike is done .

Monday-that's now 12.22.03 I've got the I've got the Can half-finished -Tomorrow it's done,the I'll carry all th my welder which is working in the Aircrafts Industry.

I did not start with the headers before I got a this extremly good Idea which is solving all the pre-conditions I need ..............,and which is btw. accompanied with some other (unexpected) Advantages...... .Here's a Detail of a RC51 Underseat Titan header-System:Rebuilt 2

That's the Cable Clutch conversion,which I've developed for RC30 and RC51.But yesterday I got the first 10 mounting Brackets for Ducati -I only have to anodize them .

Those CCC is maximum weight reduction and probably the only one worldwide,which has an adjustable declutch stroke from 0.7 - 2.3 mm . The reduction of handforce you need is dramatical,so we've measured at a OEM 749 9kg to pull the Lever ,and at a friends 995 where I've mounted the first Prototype in May 2003 we've measured 4.5 kg with my CCC . That's a reduction of 50% or otherwayround :OEM hydraulic is double heavy to pull.

Available: mid of January

Rebuilt 1

Below the 999 waterduct,incl. hose for rear cylinder at 1100 gr (2.42lbs) . For the Objectives I have : too heavy an wasting too valuable space,so I thought I should go for something new......... .

Click here: Water duct and you'll be guided to my veryfirst

Ducati-rebuilt.