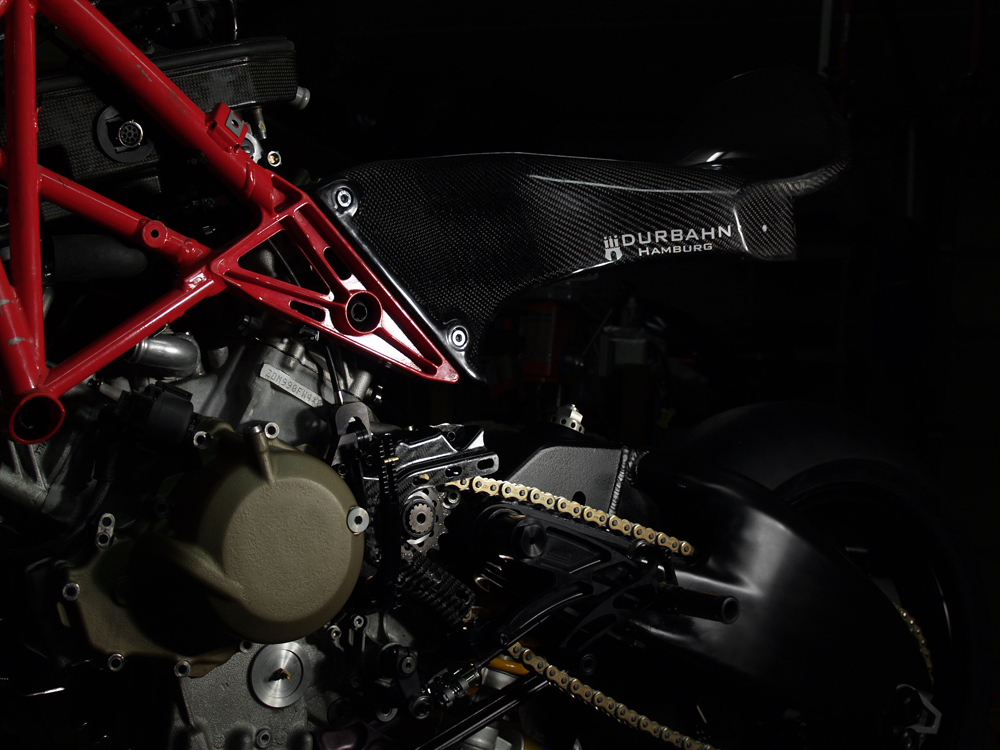

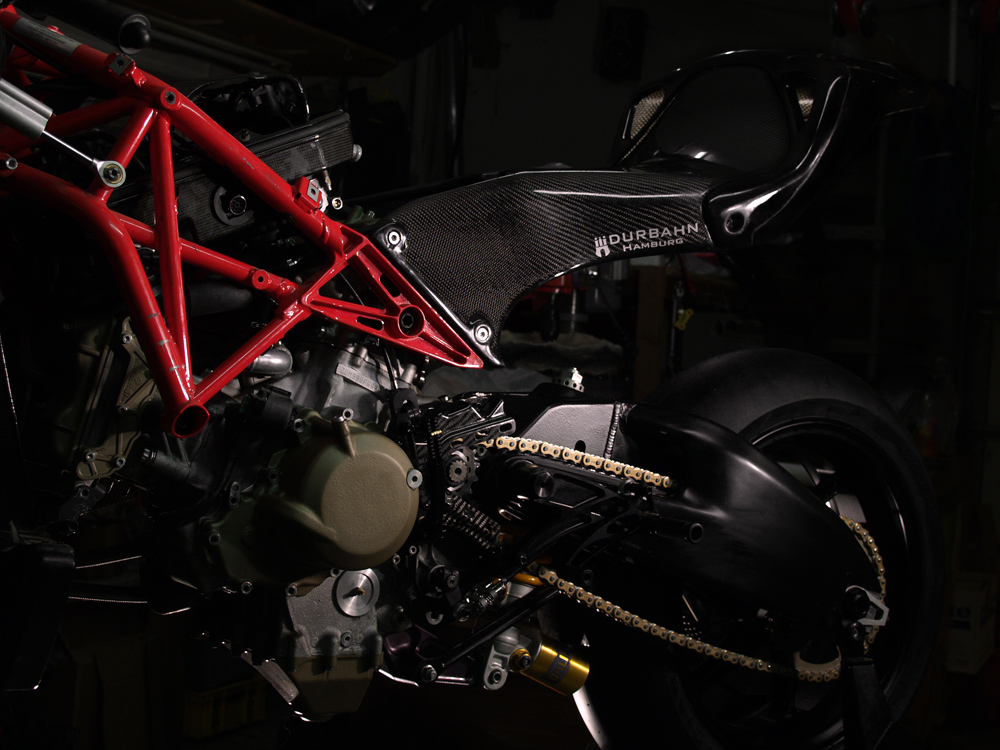

Durbahn Desmosedici

my Monocoque + Rearsets

Mai 30/11: Desmosedici Durbahn Monocoque

Now on special request available painted ready to race !

November 5/10:

To show some flow.

I've mounted the OEM Tail on my Monocoque when I made the Pic.

This is the Carbon/black Gelcoat Version which is better for painting

September 6/10:

To show some flow.

I've mounted the Termi Tail on my Monocoque when I made the Pic.

Feb 17/10:

Assembled my Rearsets for the Desmosedici outside the Bike for better Comprehension of the working Principle.

Jan 26/10:

Overview about estimated delivery-Time and some more Details regarding my Monocoque, Rearsets and the CCC for the Desmo (for more see 25.10).

Desmo-Monocoque

In about 10 Days I can start to fabricate the Monocoque.

The approximate Delivery time from the Day of Order will be 3-5 Weeks.

Preferably the Monocoque - if you like to paint it - should be build not in

Carbon fabric, I would recommend a Carbon/Black Gelcoat Version then.

The Monocoque works in Conjunction with my rearsets only, as I will not copy

the Failure of Ducati to attach the rearsets at the Monocoque (reasons

below)

The Monocoque will have all the OEM mounting Spots for Seatpad, Oilbreather,

Exhaust and Tail.

It can be build the dynamical way without - or the OEM style with flat front

lower end.

Desmo-Rearsets

The approximate Delivery time from the Day of Order will be 4-8 Weeks.

Spare parts approx 7 Days

Moreless OEM Style Carbon-Heel guards/lower fairing attachment are inside

Modelwork, and can be delivered too

Normal or GP shift Scheme possible ( depending on the shiftlever )

Height-Adjustability +/- 12mm

Delivery including new Swingarm-Axle ( Titanium or CrMo Steel ) and new

Carbon OEM Style Sprocket Cover

Can be used in conjunction with my or OEM Monocoque

Desmo Cable Clutch Conversion

The approximate Delivery time from the Day of Order will be 3-5 Weeks.

Delivery including CNC machined ISR Clutch Lever, and new Carbon Sprocket

Cover OEM Style

Pricing

Got a rough pricing in my head, but still cannot calculate 100%.

If you wanna get a rough Price range then please drop me an E-Mail.

Jan 25/10:

So far.

So good.

The first Set of my own Desmosedici-rearsets is done.

anodized

mounted - and works perfectly.

Close to a year the whole development took, but it was worth the

effort.

One year ago I already had a different rearsets Layout draft/CAD done, was close

before machining, but after watching this draft again and again during a couple

of days I felt this Layout does not fit to the Character of the D16, so I

started again thinking how the rearsets should look like.

It's - the whole appearance of the D16 is floating, and with soft curves, so I

attempted to create the rearsets the same way, a bit of how the OEM or PVM

Rims/Spokes look like. Means they should have a kinda curved "H"-Profile, which

has the lowest weight, at maximum Stability.

Well, this rearsets-Assy is far away from being done just for

beauty reasons, there have been solid intentions behind.

This D16-rearsets should:

eliminate the instability of the OEM rearsets, so improve the Stability of the whole Bike by attachment of the rearsets at the Swingarm-Axle. If you check the 2009 GP Race-Desmosedici you will detect that they have also used the Swingarm-Axle to solve the Problem of swinging rearsets.

eliminate the Possibility that at a crash the rearsets also can damage the Monocoque (because they're not fixed there)

be height-adjustable

take care for better shifting

allow to mount a way lighter and better looking Monocoque, as the necessity is gone to fix the rearsets at the Monocoque

Which leads to my new Monocoque for the Desmosedici, which is

(at present) at half the weight of the OEM Monocoque, but I think even a weight

loss of 66% is possible.

Weights:

My Monocoque: 1200 gr ( 800gr is possible)

OEM Monocoque: 2500 gr.

More details soon.

.......................

As I had to carry a lot of Bits to the anodizer I decided to finish my

especially for the D16 designed cable clutch conversion

too.

This CCC is a hopefully very smart Combination of Simplicity with Functionality,

partially based on my V3 CCC

,

but basically this CCC is refined Version of my very first CCC, which I made for

my RC30 in ~ 1995.

,

but basically this CCC is refined Version of my very first CCC, which I made for

my RC30 in ~ 1995.

A well done CC provides you with a much better feel for the

clutch, has less weight, has no leaking problems, is stroke-adjustable, and -

which is the major Point maybe - needs approx 40% less hand force compared to a

hydraulic Clutch.

My Focus was to create a CCC for the Desmo, which has all those Advantages - but

combined with a ease of mounting, and a re-enactable working Principle for the

Pilot.

Means the pressure-Spot should be found and adjusted easily, aswell as the

clutch-Stroke should be able to be changed and adjusted within seconds.

And Rock solid, and dirt/crash protected and working with needle-bearings.