DURBAHN BMW S1000RR

Start/News

Note: all special and common Products, which I have available for S1000RR you can find inside the SHOP

September 2016

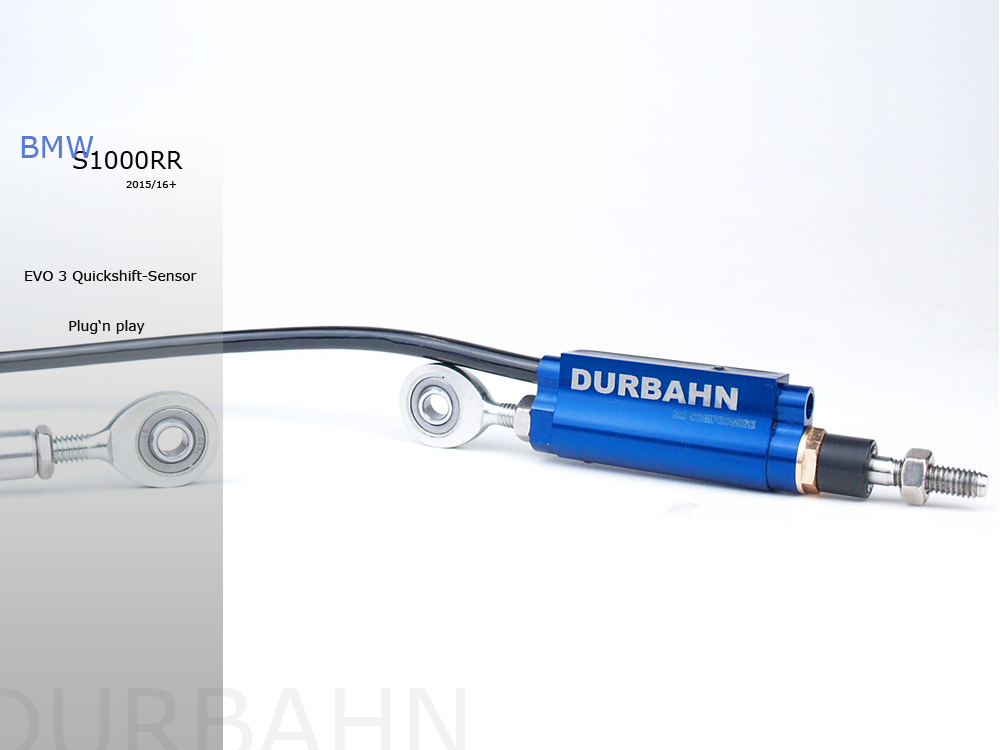

Soon available in my Shop - the

Evo III Quickshift-Sensor for the 2015-2016-2017 S1000 RR !!

February 19/2015

New Products for the S1000RR :-)

Just Check the Shop

Rearsets (available also Gold and Black)

Rear Brake Disc

EVO II+ Quickshift Sensor 2015 S1000RR - Plug and play !

EVO II Plug and Play Quickshift Sensor for all

S1000RR until 2014 !

GP Switch II, allows to bundle the main adjustment opportunities all on one Switch

February 22/2012: S1000RR Monocoque

The mold is finished, and we're able now to fab the Monocoque. But it only matches my Fueltank-Dummy, which needs to be done next.

February 12/2012: S1000RR Chassis/Suspension + Monocoque

The Fork-rebuild is now available in my Shop - aaand: the last 2 Pieces of the Monocoque Mold are done :-) so in approx 2 Days the mold can be (hopefully) disassembled.

February 02/2012: S1000RR Chassis/Suspension

So, the necessary Parts for the Fork-rebuild are machined and coated, so now the S1000RR split Damping rebuild is available inside my Shop !

February 01/2012: S1000RR

2nd Part of the Mold of my S1000RR Monocoque is growing.

January 31/2012: S1000RR Chassis/Suspension

We had to machine a few Parts, but

that's done now, and first realized the rebuild on my own Fork.

The response and feel is quite distinct, the Advantages- read below

The rebuild soon available inside my Shop (we have to machine a few Internals at present), of course including new Oil, and on request/suggestion including new Springs

January 2/2012: S1000RR Chassis/Suspension

So that's why in Moto GP/WSBK the Team changed to separate rebound and compression Adjustment, means one Fork Leg is purely responsible for compression, the other one for rebound.

This Fork-Rebuild will definitely improve the behavior of the S10000RR in a very noticeable way. There is no need at all to go for a expensive Ohlins Cartridge or similar - we achieve the same characteristics by a smart rebuild, at way lower costs including support and individual settings.

I will offer this rebuild soon. Stay tuned.

December 13/2011: S1000RR Monocoque

The mold getting started.

November 29/2011: S1000RR Monocoque

First Section of the multi-Piece mold is done.

November 27/2011: S1000RR Monocoque is in the makes - seriously.

Luis, the good Soul from Spain helping us.

Polishing

Then the wax

The final result, close to a mirror

November 4/2011: S1000RR

injection Manifold.

So this is my Idea - a Quick release height adjustable Injection Rail.

When I have to remove the Fueltank I would not even have to disconnect the Fuel

line, I simple would take it out including Injectors.

October 26/2011: S1000RR the Monocoque

the last missing Piece of

Modelwork is done.

The missing Bridge, to carry the load of the Driver efficiently.

Of course I could have build a Monocoque without that Bridge, but that would have increased the weight

October 25/2011: S1000RR Sato Rearsets now available in the Shop.

October 20/2011: S1000RR Sato

Rearsets.

Equipped with a wide range of adjustment possibilities (but still unobtrusive),

extreme Quality, perfect Optics, normal or GP shift, and the Shiftrod is still

running through the Frame !

October 19/2011: S1000RR Fuel rail.

Anodized and equipped with Ducati

injectors.

My S1000RR will run only on those 4/upper shower Injectors, I do not need any

lower Injectors.

Of course it won't work with the OEM ECU, but it will work with Motec

(M800/M880).

August 29/2011: S1000RR Monocoque Update

The 5th Time base coated.

It has to be perfect, the usual stuff can be done by others .

August 18/2011: S1000RR Monocoque Update + injection Rail

The Plastics: everything base coated again.

Assembled

The next Step, to "cut" the sharp Edges

August 06/2011: S1000RR Monocoque Update/after Cut.

The revolving edge is very sharp,

so no normal "bondo"/plastic Filler would keep the sharpness during model work.

So I decided to build this edge from Epoxy/Carbon "flour", which will survive

with it's sharpness.

Fueltank Dummy revolving edge increased to 2cm

Coating with resin/Carbon flour

Both Pieces pressed together

Removal of superfluous Material, to save Time - less grinding

work

August 02/2011: S1000RR Monocoque Update/after Cut.

Added a 90° 1" revolving edge.

Brings extreme torsional stiffness, so I will be able to realize my S1000RR

Monocoque with approx 1200-1300 gr. !

Check fitment Monocoque Model/Fueltank dummy

Positioner

Building the 2cm 90° revolving edge for the Fueltank-Dummy

July 31/2011: S1000RR Monocoque Update.

Picture Series.

Cutting Line Check

The 2 separate Units

JulY 28/2011: S1000RR Monocoque

Update.

The inside sealing contour of the upper Section of the Airbox is done.

It will belong to the "Fueltank-Dummy".

July 11/2011: S1000RR Injection upper Section

The Layout for the Injectors I've chosen before I disliked, so here's the new Layout .

July 11/2011: S1000RR Airbox upper Section- the beginning

July 07/2011: S1000RR Airbox Picture Series

July 06/2011: S1000RR Airbox Mold

Done so far, now we're going to make the first Airbox lower Section from Carbon.