Durbahn 1098 Web

Recent ...... what happened past weeks and months ?

March07/2010.

In the makes - first part of the mold:

And: The wiring with the Motec M800 and SDL

starts to look good.

first Starttest now on

first Starttest now on

![]()

Feb26/2010.

The large Air-Intakes growing.

Luis, the good soul doing the fine work.

Tomorrow they're prepared to fab the mold

Feb24/2010.

The Ducati 848 with MoTeC is in progress, just now have to smoothen the Terror of Wires.

Feb23/2010

Modelwork of my new huge Airrunners.

They "still" seem to fit perfectly to my 1098 Fairing

I hope the mold is done in 14 days, so then the first set of the large Race-Airrunners will be available in approx 4 weeks.

Jan22/2010: the CTS 5/7 Quickshifter Plug'n Play Adapter-loom done for the

"old" 916,749 to 998 Ducati's.

Soon inside the Shop.

Jan20/2010 Detail work with Deutsch-Connectors:

Still left to fab Brackets for Connectors ...

Dec 8/2009:

A Buddy of mine is building his personal 848 here, with a little help from my Side regarding Motec wiring, TC, and so on.

More Details soon.

Dec 7/2009:

The Airrunners are proceeding well.

Dec 5/2009:

Ducati 848/996/999 lightweight Radial rearbrake available soon !

Nov 30/2009:

We finally started to finish the huge Air intakes for my 1098 Race Fairing.

Sept 23/2009: BST Wheels weight.

Front 2704 gr. ( PVM Mag 2724 gr.), OEM AL Wheel 3800 gr.

Weight saving to OEM: 900 gr.

Weight saving to PVM: 20 gr.

Rear BST 2974 gr. - ( PVM 3200 gr. ) OEM 1198 AL Wheel 3240 gr.

Weight saving to OEM : 226 gr.

Weight saving to PVM AL-Wheel : 226 gr.

In total the BST's are 1.1 kg less compared to OEM , and 0.24 kg less comared to PVM ( Mag front, AL rear) .

Measured on Swiss Gauge http://www.ohaus.com

Sept 19/2009: Tech Gallery opened

August 28/2009:

Soon more Information and Pics available regarding Fueltank-Airbox Setup.

August 27/2009:

Soon to come:

The whole Explanation of this project, what is where and why is what, and so on.

July 28/2009:

July 23/2009: V3 left side Detail...what you can see

No alternator custom DRH Engine Cover

Integrated Cable Clutch Lever

4 pos height adjustable Rearsets

custom KW Shock

Exhaust Outlet left side

Carbon custom Engine breather

Infrared Tyre temp Sensors

999 DSSwingarm

July 17/2009: V3 on Track ..Battery, electrical Waterpump

Typical Situation, all the guys have lunch-Time, and it's just me sitting among the crowd of Bikes - programming.

But all in all it was very successful .

Had some Problems first 2 days until I detected a faulty Bosch Ignition Module, but after I found that Prob everything ran smooth.

First expected problem- Cooling Problem maybe due to the reworked Water-Circuit with an electrical Waterpump - nothing, perfect, 75°C Watertemp at outside 33°C Air.

Next expected problem: total loss system ( only running on Battery ) may cause Problems - nothing, I think the 9.2 AH Lifepower Battery would be good enough for 45 Minutes even with:

2 x Lambda-heating

electrical Waterpump

Tons of sensor

usual Electronic (ECU/Dash )

...sometimes I even did not charge between 2 Sessions on track.

Typical Situation...programming:

July 12/2009: V3 Summary

Quite a couple of days since the last update, but that's just because there's been no Time left to refresh this Web.

The V3 is finished, will shoot some Pics on track of the Entire Bike.

June 26/2009: V3 Update.

June 17/2009: V3 Wire Harness Day 4:

So far done with the basic Motec M800 Loom ( just soldering of Connectors left ), I started with the ADL 2 Loom.

Not too many Inputs of the ADL 2 occupied at present:

Tyre temps center/left/right

GPS

G-force X/Y/Z

Display mode/Scroll Functions/Alarm Acknowledge

June 14/2009: V3 Wire Harness.

Couldn't stand my wire Harness work from last year, so I decided to fab an new Wire Harness.

June 13/2009: V3 build-up:

Proceeding.

June 12/2009: V3 build-up:

After most of the trouble is gone now I started to build up my V3 yesterday.

May 27/2009:

After close to one year of Fight for this it finally happened, the Ducati CMC Gunmetal Edition.

May 26/2009:

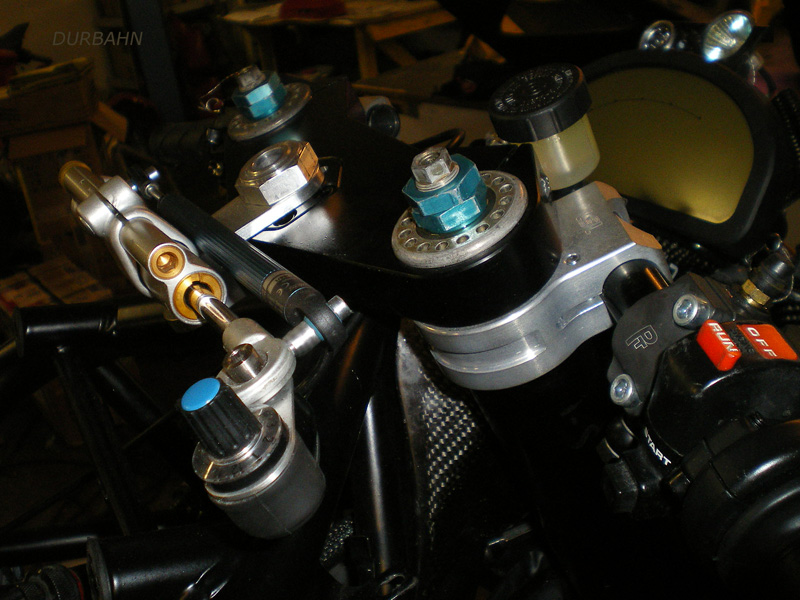

Triple Clamps done.

Available for Desmosedici OEM and FG 800 Forks.

...back from the Anodizer, earlier than expected.

In the Shop soon.

May 23/2009: Triple Clamps Ducati 1098/1198/S/R/848/ also for FG800, Offset adjustable.

Gave everything to the Anodizer, Pics Maybe on Thursday.

May 22/2000: Monocoque w/new Feature.

Carbon Fabric rear Top - soon available.

May 19/2009: Adjustable Offset Triple Clamps available in 14 Days.

For:

848/ 1098 /1198 S/R

848/ 1098 /1198 S/R with FG 800 Fork

.......................................................

Available also now, new superlight Rearbrake-Assy

December 12/2008:

Close up of my 1098/1198 Fueltank CNC-Internals.

November 23/2008:

Close to be done: CNC machined Bits which I need for my 1098 Fueltank-Setup

October 23/2008

Forgot to mention:

The Fairing shown below is a RACE-FAIRING.

No Provision for Kickstand or Headlights

More Inf's inside my Shop

October 18/2008

1098 Fairing Lower and Upper will soon appear inside my Shop.

Lower designed to hold at least 5 Liters of Fluids ( Oil/Water)

Available in Carbon/- Kevlar and Glassfiber , all build with EPOXY-RESIN

October 5/2008

Taking care about the "Fueltank-Kit", to make Life easier for me and customers when I start to offer it

Small things sometimes can make a huge difference in saving Time.

So did care about OEM wire harness, Battery Location and requirements for all those who don't want to build a new wire harness. The Waterduct looks provisionally now, which is correct. So I will make a new high-Gloss Pics same style as the Fueltank below when my sample come

back from the Welder.....

The Fuel lines /Electrics The Waterduct

My 1098 Fueltank, close-up :

September 25/2008

This Winter it'll be all about to interpret the Data, which I won during the day(s) I rode the V3.

As for average skilled people like me it is not so easy to to control even a stock 1098, you can imagine how it is to control a 1098 which has 110 lbs less than stock, lots of lbs of shaved rotating Mass ( also inside the Engine ), and at least stock Power .

So how to control such a Bike?

I've got tons of Ideas, a big Part are playing the lean Angle Sensors, which you see here as User 6 and User 7.

They detect the lean Angle very precise in dry conditions ( sufficient for me, as I do not ride when it's wet).

And they give a great opportunity to control the Hp/Nm delivery of the Engine, depending on lean angle.

Additional the steering Angle Sensor gave great insight.

So I've programmed a very simple 3D Table to attempt to find out Wheelies and height of wheelie, which would assist ( considering other Factors too) a sophisticated TC. This very raw 3D Table was just programmed to check the Values of the Lean Angle Sensors, not the Fork Position.

Of course the Fork Position is a way better Indication, but you are not able to detect the height over the ground ( as end is end ), so I checked if the lean Angle Sensors can indicate a Wheelie and it's height - and the results are very good for just being a raw Test.

Interestingly but not astonishingly the steered Angle sensor shows high fluctuation during a wheelie, especially when displayed as derivate of steering Angle Position.

This could be a great help writing some even more sophisticated Traction Control

Tyre Temps are also monitored .

But of course it all needs some refining and a bit better initial Calibration.

And I know the lean Angles are not high, aswell as the Max RPM.

But if you'd ride a Prototype, which is loosing Oil, which loosing Water somewhere... would you go for your max lean Angle ?

September 21/2008 Metamorphosis, my Fueltank-Setup : Durbahn-Design into OEM 1098 Design.

Just a few Steps, most things are already prepared.

The Situation at the beginning, my 1098 Fueltank Setup, in front the Monocoque + my Fueltank Cover OEM Design

Next then I added the OEM shaped Fueltank ( - Cover ) .

All in all the Conversion did take 2 Minutes, in the end weight wise it does not matter what you choose, as the difference is not more than 800 gr. ( or 1.87 lbs )

September 20/2008:

Test today how long it takes to implant my Fueltank into a OEM 1098.

I removed:

OEM Airbox with Throttlebodies

Cooling fluid reservoir

Lower Radiator hose (incl. Thermostat and front cylinder Radiator hose)

the front Cylinder Water-bypass-Screw (it needs to be rewelded to an L-Shape)

September 19/2008:

The V3 before the crash.

The Lambda-Recordings ( based on my 999V2 Map ) after 7 Times of reworking of Mapping.

From 999 V2 to 1098 V3,within 7 Times x 20 Minutes of Work, real Track conditions.

The Result after 7 Times remapping :

Where I started (my 999V2 mapping) :

September 14/2008:

V3 disassembly, Time now over here to tune the Engine and the remaining fine work.

From October 08 to May 09 ( no riding Season) there's Time enough to make the V3 perfect.

September 13/2008:

V3 crashed.

The first crash on track in my Life.

When I wanted to close throttle in front of the corner the Gas stuck at 73%.

I had 163km/h, that's 45 Meters per second.

The first Time in my life the Throttle stuck, and I was not clever enough to declutch.

For me it took 0,7 seconds to realize everything, and to find my personal Solution,

So after 0,7 seconds I pulled the brake-Lever as hard as I could.

From then on in 0,38 seconds the front wheel came from 163 km/h down to 14 km/h..... and I came down.

I have been very close before a massive spinning rear wheel (which could have been helpful), as I already had rear damper Position at 10mm before fully released.

The TC was not activated, because the high EMP from the Ducati Coils disturbed the Signals, so I decided to switch TC off because I anyway only wanted to

collect Data, and did not intend to accelerate hard out of the corners.

But I'm fine, nothing really bad has happened, and the trackdays have been very successful.

Got the Engine Mapping close to be perfect

Lean angle detection works perfect

Avery good balance I found between Agility and Stability

And I anyway needed new leathers and helmet and Shoes

I also found out the Reason why the Gas stuck, but that's a Story for later.

September 9/2008:

First Track-Tests of the V3 tomorrow .

A 1098 Semi-Hardcore rebuild weight Calculation:

Lets say I'd re-rebuild my V3 back to a level where it would have more Identity with a OEM 1098.

Of course each measurement would add weight, lets start.

- back to OEM SSSW Setup + 2.8 kg

- back to OEM Alternator + Rectifier + Alternator-Cover + 3.5 kg

- back to OEM Clutch ( or dry-slipper ) + 1.9 kg

- back to all OEM screws/Bolts/axles + 3.8 kg

- back to normal Ti-Exhaust ( Acra or similar) + 2.2 kg

- back to OEM Tail with Subframe + 6.1 kg

- back to std. Fueltank/Airbox/Air runner Setup + 7.3 kg

- back to OEM Battery

+ 2.0 kg

- back to OEM Brakediscs +

1.5 kg

- back to Ohlins Shock

+ 0.5 kg

------------------------------------------------------------------------

That's

31.6 kg or 70 lbs

So we'd have then a 1098 with :

Real light Fork ( each Fork leg should not be more than 3.2 kg)

Ti-Exhaust

Light fairing, as mine

Mag or Carbon Wheels

Light Callipers ( Brembo GP Calipers which are~ 680 gr each )

Light Triple Clamps ( ~1550 gr )

No lights

The usual track rebuild. Such a 1098 should end up at 167 kg without Fuel.

September 4/2008 , my Fueltank - Airbox Setup ( for 848 and 1098/S/R).

As I receive more and more Inquiry's about that Setup, here's a short note:

I will start with the Production of this Setup end of September to make it available to the Public.

August 26/2008:

Pic from today, lot of Stuff done Background.

Airbox closed now

Have to fab my own front Fender because all Carbon-Fender on Market are 300 gr. or more

So made my own mold, goal significant less than 200 gr.

August 25/2008:

Minor Corrections on leaks today, sealing of Sensors and Pinholes where I had machined too much from the " No Alternator " Cover. Some reprogramming of Injection Timing at Idle.

Well in the End while I was taking Pics my Girlfriend wanted to have a little bit Attention too.

So I drove home .

To write the necessary Tables at Home.....

August 24/2008:

V3 is running !

Was not easy today, but got it finally.

Cam- Sensor needed to be relocated and I had to fab a custom one, because:

Here's the Screenshot (light blue is Scope Cam Sensor-Signal ) before, means OEM Location.

But for a ref/sync Setup I had reworked the Camgear, and the Sensor view from top onto the gear gave no signal with distinct Indication, so I had to go for a Sensor-view onto the gear from the side ( as 999 models)

Thankfully my clutchcover was already prepared, just had to remove the Plug and to fab a custom Sensor:

..and then the Signal was fine

Calibration with a 360° Scale and a TDC-Clock

so far so good the whole Setup is free of failures at present

August 23/2008:

Muffler is done.

Just the costs for the Muffler ..... no tubing involved.

Raw Material 650 Euro ( ~ 950$)

Bending/Folding 750 Euro ( ~ 1100 $ )

Welding 500 Euro (~ 750 $)

+ the Time of labour from my side ~ 60 hrs.

Initial testing today , Motec ref/sync alignment needs to be adjusted.

Will do that tomorrow.

August 17/2008

Daylight Pics from today

Routing of wires.

Sensors mounted at present:

Rear Wheels Speed Sensor, Resolution 40 Impulses/Rev (Durbahn)

Tyre Temp left rear (Durbahn)

Tyre Temp Center rear (Durbahn)

Tyre Temp left rear (Durbahn)

Suspension rear (P+G)

Lambda cylinder rear (Bosch 5 Wire LSU 4.9)

Quickshift-Sensor ( Tellert)

Cam/Sync Sensor ( OEM Ducati/Bosch)

Crank/Rev Sensor ( Bosch )

Watertemp ( OEM Ducati )

MAP/Airbox Pressure ( Mitsubushi/ Honda)

Airbox Air Tem Sensor fast response ( Honda )

Lambda cylinder front (Bosch 5 Wire LSU 4.9)

Steered Angle Sensor (P+G)

G-Force Sensor (X/Y/Z Axis)

GPS Module

Suspension front (P+G)

Clutch Lever Position ( Durbahn)

Lean angle Indicator right

Lean angle Indicator left

Front wheel Speed 40 Impules/Rev (Durbahn)

Indication-Lights :

- Shiftlight

- TC Working LED

- Warning light for important case sensitive Failures

ADL2 Alarms:

- Approx 40 different Alarms configured at present

ADL2 Outputs - all used

ADL2 - Approx 50 of 79 Pins used

M800 Inputs - all used

M800 - Approx 50 of 68 Pins used

OEM Ducati left side Switch unit reworked for ADL2:

Display Mode change

Scroll line up Button

Scroll line down Button

Alarm Acknowledge Button

TC off/on

Fuel reset

Laptimes reset

High Amp Auxiliary Precision 5 Volt Power supply added

Communications :

ADL2 to M800 : Can-Bus

ADL2 to PC : USB

M800 to PC : CAN

Number off logged Channels at present : 105

Number of wires /all different colours : 115

Slipper-unit by Air-valve , braking Moment programable

August 16/2008

The last Step of welding my Canister will start on Monday.

I expect it back from welding on Friday August 22

That means including some table which need to be written I maybe able to start the 1098 the first Time at all on Sunday 24/August.

All in all I estimate the muffler only has taken approx 120 hrs of work.

August 8/2008

On the Scales today.

5.5 liters of Fuel

Full of Water

Full of Oil

Missing: Battery ( 1.3 kg )

Exhaust Package/Tubing ( 1.3 kg )

Weight 137 Kilos.

August 7/2008

Fine work again.

Detail Pic.

August 6/2008

Fine work and Fine work and...so on.

Most will not notice that anyway, so I made no Pics.

Talking about wires and programming and Sensors, bunch of work

And some misc Notes:

- added steering angle Sensor, which might be very helpful for calibration and supervising of Sensors ( safety Issues ), aswell as maybe to have some small Influence in Traction Control.

- The lean angle Sensors I've mounted do have a xtreme fine and repeatable resolution, but still not clear how they work in real Life

- But there's of course a conjunction between I.E: lean angle left and tyre temp left and the Maximum of torque you can bring onto the ground ( of course some other influencing variables too ), so I already started to program some tables.

- I'm close to have occupied all In-and outputs of the M800 and ADL2 , have ~ 105 different wire colors at present, the Number of logged Channels inside ADL2 is 102.

One Pic from yesterday.

August 3/2008

– Moto GP (4 stroke) minimum weights

2 cylinders or less motorcycle 133 kg

3 cylinders motorcycle 140,5 kg

4 cylinders motorcycle 148 kg

5 cylinders motorcycle 155,5 kg

The truck-Bike Race series WSBK do have a minimum weight of 162.5 kg

At the end of a Race, so if possible- without Fuel.

I think I could reach the 133 kg ( 293 lbs) easily if I would remove the Starter.

But I like the Comfort.....maybe I reach the 133 even with starter.

July 27/2008

All about programming and details.

Detail- removed Oil Filter Cover/housing

The entire Bike at present:

July 24/2008

The Bike at present.

Missing ( weight estimated):

Water 2.6 kg ( seems to be less , 2 August)

Oil 2.8 kg

Wire harness 0.8 kg (actually 0.9 kg , 2. August )

Batterie 1.8 kg ( I think I can get way with 9.2 Amp, so 1.3 kg )

Sensors and Relays 1.0 kg

ADL 2 0.5 kg

M800 0.4 kg

Brakelines incl. Fluids 0.4 kg

left Handlebar 0.3 kg

Exhaust Package + inner tubing 1.3 kg

front Fender 0.25 kg

Seatpad 0.18 kg ( actually 0.13 kg , 25.July )

Waterpump Internals 0.10 kg

Belt Covers 0.25 kg ( actually 0.18 kg , 25.July )

Windscreen 0.35 kg ( actually 0.375 kg , 2.August )

added Steering Angle sensor 0.07 kg ( 4. August )

Subtotal: 13.03 kg

Well, its not quite clear at present, how everything turns out, but on bathroom scales the Bike showed 63 kg front 57 kg rear , which is 120 kg at present.

Bear in mind bathroom scales can show too much or too little weight.

So there's a good chance to reach the focussed 136 kg including starter and all fluids, just without Fuel.

July 23/2008

Snapshot today

July 20/2008

Slowly but surely my 1098 grows

July 16/2008

Got the Titanium-muffler/housing

And: the Final assembly of my 1098 has begun.

July 15/2008

The Muffler is growing.

A Buddy of miner made the first Prototype from stainless steel ( Picture) , and a second one from Titanium... which I hopefully will receive today.

'

'

July 11/2008

1098/S/R Carbon Fairing.

Available only on special request... at present.

July 08/2008

Bunch of News:

My Carbon fairing lower ( available now, as well as upper fairing ) , the weight in gr.

July 07/2008

Due to my new Crankcase Cover Design I was not able to fit my own CCC.

But already at the raw layout of this Cover I've known the CCC wouldn't match, so I've designed a new Cable Clutch actuation, which ( Clutch-Lever, redirection-Drum, Cable, lever at the Engine ) in total is only 330gr., that's 0.728 lbs !

Also: "Alternator" Side reworked

July 05/2008

My 1098 Engine is getting complete.

Right Side wet Clutch Assy is close to be done

The Wet-Clutch:

July 03/2008

The headers left Side

July 02/2008

Started with my 1098 headers today.

Attempted to go for as much of header-length I was able to create within the little Space I had.

July 01/2008

Ducati Desmosedici, will start to fab Parts for it starting from now.

Looks like I will have to open a Desmosedici Web soon, as I will do much more.

A couple of OEM Parts which needs to be reworked a bit, and copyed with approx half of the weight and smart Solutions, for race and road Desmos.

Later then more Desmo Parts, as light rear Brake, Fueltank...... Motec ECU, Traction Control and so on.

Approx 90 lbs I'd like to shave from the Desmo.